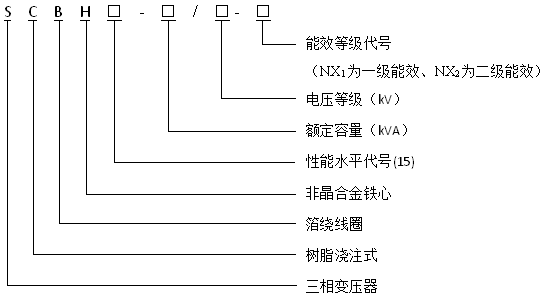

SCBH15 Non Gold Alloy Dry Type Transformer

The amorphous alloy dry-type transformer uses an iron core made of amorphous alloy strips that can significantly reduce no-load and load losses. Its no-load losses are reduced by 75% compared to ordinary dry-type transformers, and the load losses are reduced by 15% compared to ordinary dry-type transformers. Amorphous alloy dry-type transformers have stable operating performance due to their low loss, low heat generation, and low temperature rise, and can be widely used in areas with high power load fluctuations such as highways, urban infrastructure, and residential communities. Due to its significant energy-saving effect, it reduces fuel consumption for power generation, thereby reducing pollution to the atmospheric environment, making it an energy-saving and environmentally friendly dry-type transformer.

Execution standards

1. IEC60076-11 Dry type power transformer

2. GB1094.1-2013 Power Transformers

3. GB1094.11-2007 Dry type power transformers

4. GB/T22072-2008 Technical parameters and requirements for dry-type amorphous alloy iron core distribution transformers

Execution standards

Performance characteristics

1. Strong resistance to thermal shock and high overload capacity;

2. Insulation materials are flame retardant, self extinguishing, and have high fire resistance performance;

3. Low loss, low noise, and low partial discharge;

4. Easy installation and low overall operating cost;

5. Good three proof performance, insensitive to temperature and dust, small size, light weight, and easy maintenance;

6. Safe, reliable, energy-saving, and easy to recycle after its lifespan, it can be widely used in harsh environments with high fire protection requirements, large load fluctuations, and dirty and humid environments.

technical parameter

| 额定容量(kVA) | 电压组合(kV) | 联结组标号 | 空载损耗(W) | 空载损耗(W)(120°C) | 空载电流% | 短路阻抗% | ||||

| 高压 | 分接范围 | 低压 | 1级 | 2级 | 1级 | 2级 | ||||

| 30 |

6 6.3 6.6 10 10.5 11 |

±5% ±2×2.5% |

0.4 | Dyn11 | 70 | 70 | 675 | 740 | 1.6 | 4 |

| 50 | 90 | 90 | 950 | 1000 | 1.4 | |||||

| 80 | 120 | 120 | 1310 | 1380 | 1.3 | |||||

| 100 | 130 | 130 | 1490 | 1570 | 1.2 | |||||

| 125 | 150 | 150 | 1760 | 1850 | 1.1 | |||||

| 160 | 170 | 170 | 2025 | 2130 | 1.1 | |||||

| 200 | 200 | 200 | 2405 | 2530 | 1.0 | |||||

| 250 | 230 | 230 | 2620 | 2760 | 1.0 | |||||

| 315 | 280 | 280 | 3295 | 3470 | 0.9 | |||||

| 400 | 310 | 310 | 3790 | 3990 | 0.8 | |||||

| 500 | 360 | 360 | 4635 | 4880 | 0.8 | |||||

| 630 | 420 | 420 | 5585 | 5880 | 0.7 | |||||

| 630 | 410 | 410 | 5660 | 5960 | 0.7 | 6 | ||||

| 800 | 480 | 480 | 6610 | 6960 | 0.7 | |||||

| 1000 | 550 | 550 | 7725 | 8130 | 0.6 | |||||

| 1250 | 650 | 650 | 9205 | 9690 | 0.6 | |||||

| 1600 | 760 | 760 | 11145 | 11730 | 0.6 | |||||

| 2000 | 1000 | 1000 | 13725 | 14450 | 0.5 | |||||

| 2500 | 1200 | 1200 | 16310 | 17170 | 0.5 | |||||

| 1600 | 760 | 760 | 12280 | 12960 | 0.6 | 8 | ||||

| 2000 | 1000 | 1000 | 15115 | 15960 | 0.5 | |||||

| 2500 | 1200 | 1200 | 17895 | 18890 | 0.5 | |||||

Structural characteristics

1. The iron core is rolled from amorphous alloy strip and adopts a rectangular cross-section, four frame and five column structure;

2. The iron core is usually rectangular, and the corresponding high and low voltage coils also adopt a rectangular structure. Moreover, the loss of amorphous alloy increases by 60% after being subjected to external stress, so the high-voltage coil of amorphous alloy dry-type transformers is usually a rigid structure cast with epoxy resin, and the iron core is suspended on the high-voltage coil without stress;

3. The low-voltage coil is a foil type coil made of copper foil, while the high-voltage coil is wound with H-grade strength enameled wire. It adopts a glass fiber reinforced epoxy resin encapsulation structure, which has good moisture resistance and crack resistance;

4. Due to the use of an iron core suspended on the high-voltage coil structure, the main load-bearing components of amorphous alloy dry-type transformers are clamps and high-voltage coils. Experiments have shown that the epoxy cast rigid body structure of high-voltage coils has strong mechanical strength and can meet the requirements;

5. Equipped with a temperature protection control system, it provides assurance for the safe operation of transformers.